Dealcoholisation

Aroma Recovery

Aroma Add-Back

Impactful aroma

recovery with adsorption

Our Technology

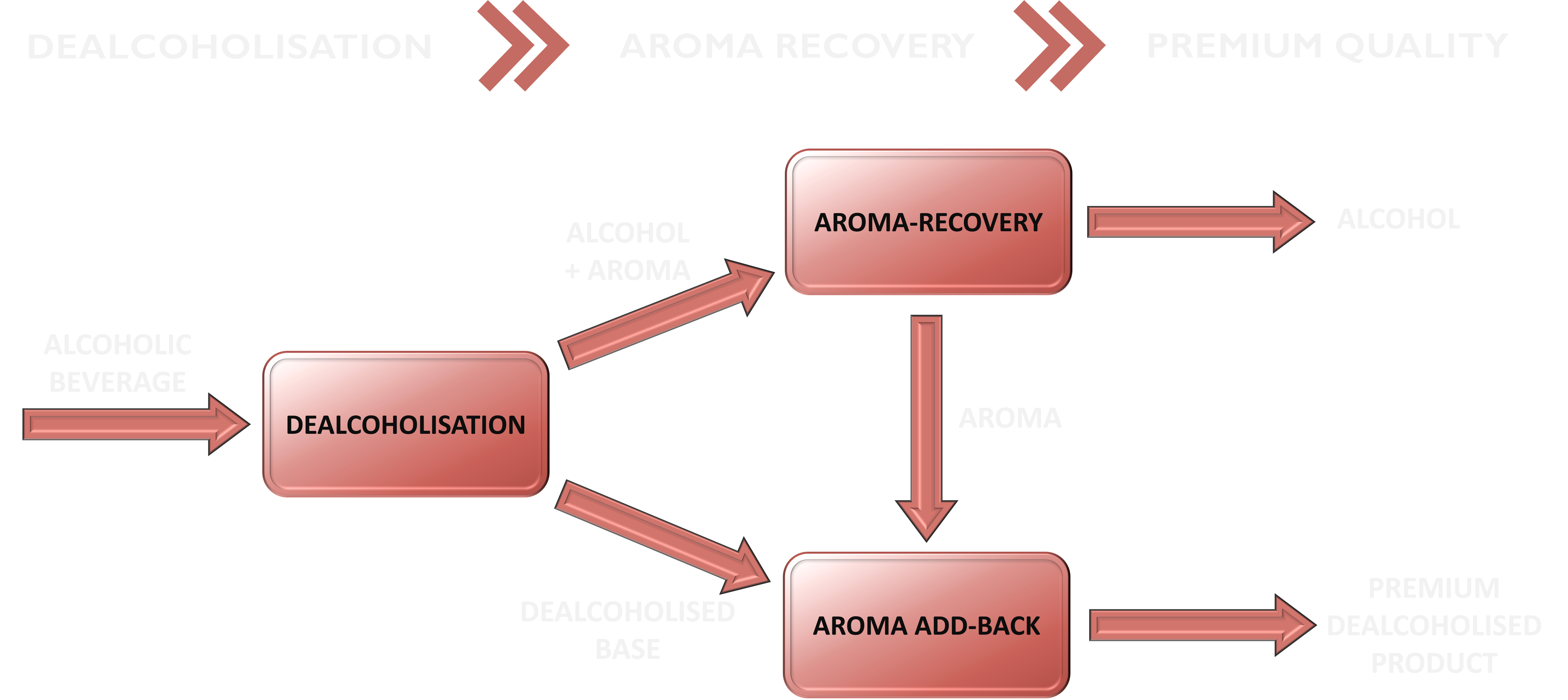

What‘s the key to making a quality non-alcoholic beer, wine or spirit? The aroma! This means preventing damage to it from heat and oxygen, and keeping as much of it as possible in the product.

Typically, alcohol is removed from the product with vacuum distillation. This low-temperature process prevents heat damage to the base. However, a lot of the aroma still leaves the product with the alcohol, leaving you with a bland alcohol-free base and an aromatic distillate. That‘s often where the story ends. In fact, most wine processers sell their distillate as brandy, it‘s that full of aroma!

Here‘s where we differ. Our patented aroma-recovery technology separates the aroma from the alcohol by adsorption. The aroma compounds bind to a special filter material while the ethanol passes through, then are later washed down into a concentrated aroma-phase. The know-how we‘ve developed in this area makes our technology one-of-a-kind, achieving a recovery well beyond existing processes.

The aroma can now be added back to the dealcoholised base without the alcohol, resulting in a product with its original aroma quality.

This is how you stay true-2-aroma and make truly authentic and enjoyable dealcoholised beverages.

Boosting Dealcoholisation

Phases of the

Aroma Recovery

Phase 1:

Adsorption / Capture

The aroma-containing feed, e.g. the distillate from dealcoholisation, is fed into the column. The aroma is adsorbed from it onto the solid phase. The liquid leaves the column deodorised.

Phase 2:

Desorption / Harvesting

Once the filter is saturated, a suitable desorption agent is used to wash the aroma down from the solid phase. A concentrated aroma phase results, which can then be added back to the dealcoholised product.

Real aroma recovery

- Retention of your product‘s hard-won quality aroma profile despite dealcoholisation.

- Realisation of a broad range of final product alcohol concentrations, even down to < 0.05 % ABV.

- Recovery of aroma from both liquid and gaseous phases in the exploitation of diverse feeds.

- Natural and authentic aroma intensity while adhering to legal requirements.

- Gentle processing conditions and exclusion of oxygen for long-term product stability.

- High degree of flexibility and adaptability to existing production facilities and processing schedules.

- Exploration of a new dimension in product development and optimisation.